OK OK... I was hoping to get a little farther along before I posted but I'll bring you up to speed.

First I would like to mention to never try this outside. In Florida leaves fall in the spring as opposed to the "fall" as in most parts of the country. It's been a real pain to keep everything clean to get anything done.

I was hoping to get the entire deck cored before I popped it from the mold but when I was inspecting it I notice that the warping of the hardi board I mentioned earlier had gotten much worse and had to go ahead and break it free and let it rest of the plywood underneath. Breaking it free went fairly well and only had a few places where it appears some of the resin wasn't properly catalyzed during the layup. Most likely due to one of my helpers who couldn't understand why we couldn't just dump all the resin and hardener into a five gallon bucket to speed things up. It appears to have only affected the matt layer and should be easy to repair once I can flip it over.

I had to use a regular screw driver to get the wood from the hatch recess. Came out without too much trouble though.

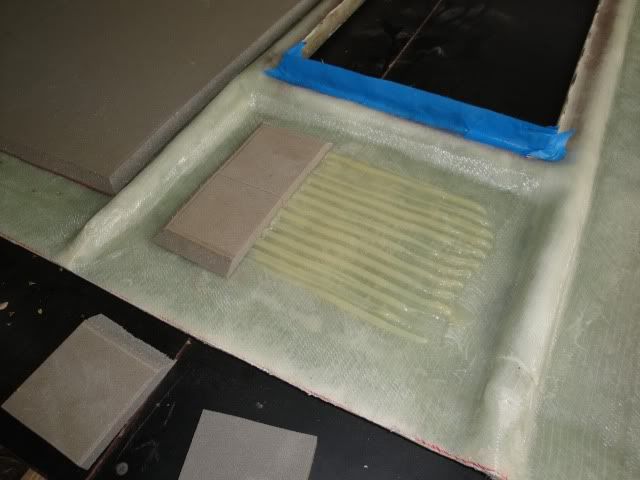

After serving as the best man in a fellow SeaCraft owners wedding I was able to get started with the bedding of the coring this afternoon.

An allergy attack sidelined me after about an hour so I hope to finish the coring up this week and get the deck ready for a trial fit.......