|

|

#1

|

|||

|

|||

|

I said back in the spring that i would post some before and after pix of my refit so here are my phase one motor restoration before and afters- right much other work to be done on the boat both cosmetic and mechanical- I rewired the boat completely two years ago so that is done. Hopefully I will get another 10 years or so out of the 350 PCM/Mercruiser Hybrid

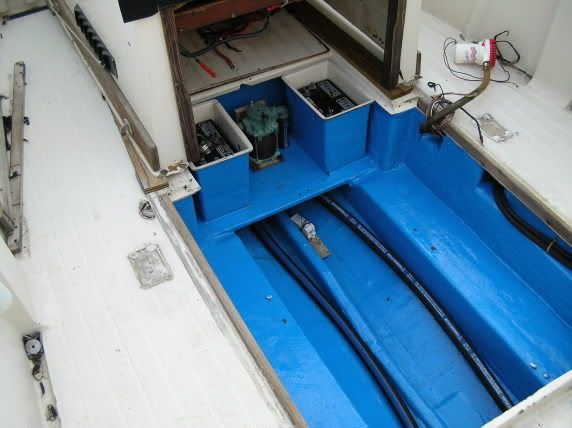

The compression on all the cylinders was fine , total cost for me so far is ~3500$. I paid a friend to do my motor work for me this time around cause I really just didnt feel up to it. 3 back surgeries and a host of other medical problems and mama said go ahead and let someone else take care of my motor so I jumped on that. Not an easy decision for me though as I dont like anyone tinkering, messing with my boat/ motor, anything- but me- But Danny is the man though and I do trust ed him to do my work and you can tell the kind of work he did. the pix dont do it justice either.The remainder of the work I will probably do on my own. Recoring two hatches and some awlgrip, we will see. . first the way my boat looked right before I pulled her out of the creek-old pix , the bilge and out of sight hoses that could have caused big problems- remember this motor was running sweet when I removed her. There is another thread talking about Holly carbs pros/cons etc. The flat top marine holly on this motor took about 7 years to dial in. I refuse to touch it at this time so it was not pulled/reworked etc. anyways- next i will be doing some deck work/ maybe new fuel tanks depending on how the current ones look, they are around 10 years old, and putting her all back together so I can at least get some meat time this year- pretty self explanatory- PS- my boat looks discusting minus everything and all tore up . So much so it is a little embarressing, so the end product will be much better- (slimed and bloodied up). The compression on all the cylinders was fine , total cost for me so far is ~3500$. I paid a friend to do my motor work for me this time around cause I really just didnt feel up to it. 3 back surgeries and a host of other medical problems and mama said go ahead and let someone else take care of my motor so I jumped on that. Not an easy decision for me though as I dont like anyone tinkering, messing with my boat/ motor, anything- but me- But Danny is the man though and I do trust ed him to do my work and you can tell the kind of work he did. the pix dont do it justice either.The remainder of the work I will probably do on my own. Recoring two hatches and some awlgrip, we will see. . first the way my boat looked right before I pulled her out of the creek-old pix , the bilge and out of sight hoses that could have caused big problems- remember this motor was running sweet when I removed her. There is another thread talking about Holly carbs pros/cons etc. The flat top marine holly on this motor took about 7 years to dial in. I refuse to touch it at this time so it was not pulled/reworked etc. anyways- next i will be doing some deck work/ maybe new fuel tanks depending on how the current ones look, they are around 10 years old, and putting her all back together so I can at least get some meat time this year- pretty self explanatory- PS- my boat looks discusting minus everything and all tore up . So much so it is a little embarressing, so the end product will be much better- (slimed and bloodied up). Prior to hauling my ride....   Motor removed  After two years since last wax job and boat sitting in a slip the shine from Collonite fleetwax still shines on    Broken motor mount-      old plumbing  My muffler had some cracking in the pieces shown so some glass repair was done. After wrapping with glass cloth and resin the sheetmetal was waxed and staystrapped around the partially set up resin- when the resin repair cured the metal piece peeled right off and left a nice flange for the exhaust to clamp to.  All sanded down , parts being reinstalled including the tranny- tranny got new rear seal, flushed etc. borg warner - velvet drive 1.52-1  Heads sanded and painted BEFORE exhaust manifolds installed- its pretty tough to paint them after. the exhaust /mating surfaces were all milled for a perfect fit as were all the new parts- water pumps risers etc.  All put back together, painted and ready to go back to her home!!!   That pretty new powerplant cant go back in the boat without cleaning and repainting the bilge- 2 part epoxy paint I have always thought my stainless keel under my running gear was aftermarket stuff bought by the police (former police boat in its early life). However if you look closely you can see where the keel is bolted through and it appears that pads were made in the hull for this purpose and maybe it was a seacraft factory option.   Dropping her back in the boat, it was getting dark so the pic is not great  And here are a couple of shots with her set in, lined up and bolted back in place. The motor mounts use stainless lag bolts that screw directly into the huge seacraft- foam filled stringers- They are epoxied in so as they will need to be heated in order to remove them.     I hope this post isnt too boring and will maybe help someone else along the way- more to come-craig

__________________

"Lifes too short to own an ugly boat" |

|

#2

|

|||

|

|||

|

Great stuff Craig, keep it comming!!!!!!!!

|

|

#3

|

|||

|

|||

|

Craig, that is MAJOR progress. Looks great. Hope all is well for you and mama. Where's Mike during all of this? Not sure my girl will be back in time for the fall run but I sure would like to fish with you guys again! Keep it up, and the pics. as well. Mike.

|

|

#4

|

|||

|

|||

|

hey Mike, Chance- thanx a bunch-good to hear from ya mike- not sure right now when i will have mine all back together and ready to fish- no hurry really, money will be the biggest factor- (two kids in college now)- Mike is doin great, he has an old restored 78 23'3 formula that we fish often so you for sure have a ride when you come up. see ya- craig.

__________________

"Lifes too short to own an ugly boat" |

|

#5

|

|||

|

|||

|

Ha Miles;

I have always kind of liked the idea of a straight inboard 23’ but after seeing all you had to go through to replace and repair the power plant. I am convinced outboard power “for me” is the way to go. You did a great job and I know the ride must be fantastic But 4 bolts and redoing the transom every once in a while sounds more like my bag. I wouldn’t know where to start on your inboard project. FellowShip _______________________________________________ My motto: Just for the Grins

|

|

#6

|

||||

|

||||

|

yo craig

I don't know squat about dem inboards but it appears you did a nice clean job!! The only thing I would have done differently had it been mine was paint the bilge Gucci Green

__________________

1978 23' Superfish/Potter Bracket 250HP -------- as "Americans" you have the right to ...... "LIFE, LIBERTY and the PURSUIT of a Classic SeaCraft" -capt_chuck |

|

#7

|

|||

|

|||

|

Looks great!!!!.. just don't forget to paint the shaft coupling.. she's looking a bit shabby next to that pretty engine...

__________________

Don Battin Pipe Dreams Marine "Design her right, Build’er well Bend the throttles, And let’er eat…." Carl Moesly |

|

#8

|

|||

|

|||

|

Craig, Nice!

Nothing beats the look of a fresh inboard!!  I can smell it now, fresh rockfish wrapped up in al foil cooking on the intake manifold ..... yum !!  - Nick |

|

#9

|

|||

|

|||

|

hey guyz thanx a bunch- other than the motor though my boat really looks like sheet. Thanx Chance-Nick I use that tinfoil treat right often- nice hot sandwitch on a cold day is always nice !!! Chuck- no green gucci for me ! Lotsa bloody decks and blood pumping out the bilge is my kinda gucci!!! (that and teak,lol). Hey Don, that aft deck is coming up and the remainder of the bilge will be painted also, including that coupling. Since I have worked for the navy for 30 plus years now , i generally like to paint anything that doesnt move! I do have a question for you though, after I remove the hatch and do tank inspection if they look bad then I will probably replace them. Do you make them??? Ill get back with you via phone or b-mail if you do. Fellowship- the motor itself is easy to work on and so are the different systems associated with an inboard. my biggest pia was dissasembly of all the electronics, t-top , wiring , console etc. Took me a couple days to do that. Ill update theis post with pix as i go along. wont be fast though- craig

__________________

"Lifes too short to own an ugly boat" |

|

#10

|

|||

|

|||

|

Nice work Miles

, looks like your doing it right! That bilge looks great all cleaned up keep up the great work. , looks like your doing it right! That bilge looks great all cleaned up keep up the great work.

__________________

I support the I'm glad I can afford one boat theory! |

|

|

|