|

|

#11

|

|||

|

|||

|

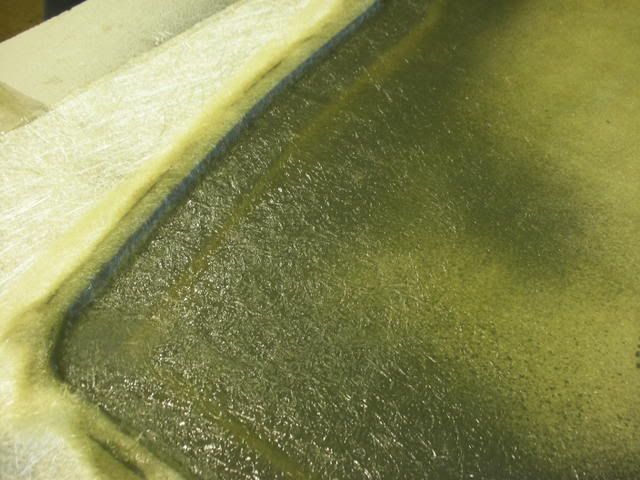

well today was the layup day.I tried to take as many pics as time would allow. The time constraint was tight with the laminating process. I waxed and sprayed the the mold on friday to have it set. We started off with the duratec this morning, using 1.5 gallons sprayed with a cup gun. after this we cut two layers of mat to size staggering the joint on each layer.The most important part of the lay up is the first two layers of mat,becuase you cant have any air bubbles for voids. we didnt start until the duratec got tacky.

we used white duratec and gray duratec as the backup    these are my two friends / proffessionals that came to help me laminate the deck. after doing all the layup it was way too much work for one person. during the layup 2 of us were rolling out and 1 guy was smoothing out.   here we are dry fitting all the coring and marine ply. The coring is really easy to work with.  its definitly not rocket science laying the coring and the wood blocks we kept the coring in about an 1.5 inches around the outside and the hatches.    The Devilet putty has the texture of coolwhip it to gets mixed with MEKP. we applied it with a 1/4 notched trawl for laying tile. this stuf is a mess and it gets everywhere. One thing we goofed on was not marking where some of the pieces were from and after some head scratching were figured it out. After everything was set in place we back filled any voids with the putty and put a 45 degree radius on the access hatches were we had left the 1.5 inch space for the final layup.      well sunday am we are layng up the final 2 layers of glass. so far we have using 8 gallons of polyester which is right on what we expected. till next time

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

|