|

|

|

|

#1

|

|||

|

|||

|

Quote:

Quote:

I will paint it for you if you want I will paint it for you if you want  Quote:

__________________

http://www.boatbuildercentral.com/  my rebuild thread: http://www.classicseacraft.com/commu...ad.php?t=22090 |

|

#2

|

|||

|

|||

|

|

#3

|

|||

|

|||

|

roll over cradle is finished, now just have to roll it outside and get a piece of equipment to pick and roll. *

__________________

http://www.boatbuildercentral.com/  my rebuild thread: http://www.classicseacraft.com/commu...ad.php?t=22090 |

|

#4

|

|||

|

|||

|

A few pictures of the flip. *Have a short video on another phone. * The google gallery for this build has all the pictures. *

Rolled it over almost all the way. removed casters from top and relocated them to the bottom before setting it all the way down. *Spun the hull around and rolled it back in the shop (bow first)

__________________

http://www.boatbuildercentral.com/  my rebuild thread: http://www.classicseacraft.com/commu...ad.php?t=22090 |

|

#5

|

|||

|

|||

|

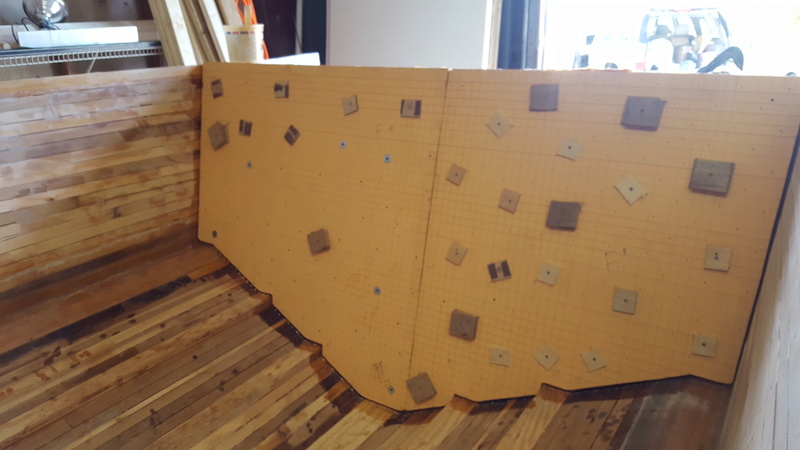

starting the interior glassing...

Started glassing. *

__________________

http://www.boatbuildercentral.com/  my rebuild thread: http://www.classicseacraft.com/commu...ad.php?t=22090 |

|

#6

|

|||

|

|||

|

Joel, How many times do we say - "Use the right tool for the job!"

You don't use an excavator for a crane! - well, unless it's a lot cheaper! (Remember, we're all a lot like Don V. - the cheap Bas#@&d) PS - The boat looks cool |

|

#7

|

|||

|

|||

|

Quote:

That thing had an extendable arm that reaches well over 16', could probably roll over a boat twice the size. "turned" out to be the perfect tool for turning That thing had an extendable arm that reaches well over 16', could probably roll over a boat twice the size. "turned" out to be the perfect tool for turning

__________________

http://www.boatbuildercentral.com/  my rebuild thread: http://www.classicseacraft.com/commu...ad.php?t=22090 |

|

#8

|

|||

|

|||

|

"and the digger was free"

As T-3 would say...."free is for me and that makes it the right tool"

|

|

#9

|

|||

|

|||

|

Quote:

Tank comes out. Lift hull off trailer with fuel fill hose. Wait til morning. Repeat as necessary. Fall for the race boat. Shine, Wish you were my neighbor. Bones too. Sweet work. |

|

#10

|

|||

|

|||

|

transom core is epoxied in place.

Dry fit, wet out surfaces with neat epoxy, apply epoxy glue (a mix of silica and wood flour), clamp/screw into place. both surfaces were very flat with a very nice fit, did not need a ton of glue. Used about 2 quarts of epoxy (before thickening) Total core thickness is 2.25" Design did not call for that much, but a had the 1.5" foam core, and it didnt add much weight. With the full size bracket, the loads are spread out over a large area, so the transom core really only needed to be 1"

__________________

http://www.boatbuildercentral.com/  my rebuild thread: http://www.classicseacraft.com/commu...ad.php?t=22090 |

|

|

|