|

|

#71

|

|||

|

|||

|

Nice work and you will love that motor with $4+ gas prices.

- Nick |

|

#72

|

|||

|

|||

|

Hi Billy

I noticed that you have exposed plywood on top of your transom where the motor would sit. What are you going to cover it with? The previous owner of my boat installed an aluminum plate over the transom to cover up the cracked fiberglass and exposed wood. I have to replace my transom and was not sure what cloth can make a sharp wrap aroung the top without getting air pockets. |

|

#73

|

|||

|

|||

|

Tashmoo I took the grinder an hit both sides of the transom about 3 inches down on both sides. I cut some mat to lenght. THe first peice was 3 inches wide and the next was 5 inches wide . I wet them out on a piece of cardboard and let them sit for a couple of minutes for the resin to start breaking down the starches in the mat. then I laid the skinner one on first rolled it a little bit then set the wider one on and rolled it all out. Once mat is wetted out it can make pretty sharp turns before the strands start popping out. after it set up I hit it with 40 grit to knock and goobers off than started fairing it out with quick fair. Dont use cloth by itself you will be able to peel it off after it sets up. I wiped the surface down real good with acetone before I laid the glass up this helps the polyester resin absorbed in the plywood.

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

#74

|

|||

|

|||

|

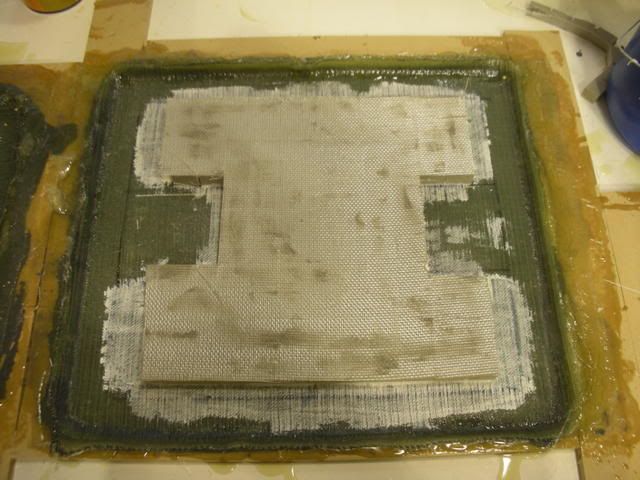

its hard to keep the motivation going when I hate fairing and sanding but I am still making progress,

got the transom top reglassed    here is the rough opening for the scupper It is glassed all around and I started fairing it in  had some leftover cabinets from a house renovation and they were the right price  so in the begining of the week I worked on straightening everything out in my garage. I couldnt deal with the mess anymore. so in the begining of the week I worked on straightening everything out in my garage. I couldnt deal with the mess anymore.

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

#75

|

|||

|

|||

|

Excellent project. I don't know how I missed it! The deck lamination is top notch. Thanks for shareing.

|

|

#76

|

|||

|

|||

|

well after ordering another boat load of supplies from Merton Fiberglass in MA.(no pun intended!) Joe has helped me out alot during this project, He is always willing to answer questions, I got started on some other projects . I got some MORE sanding done and fairing.

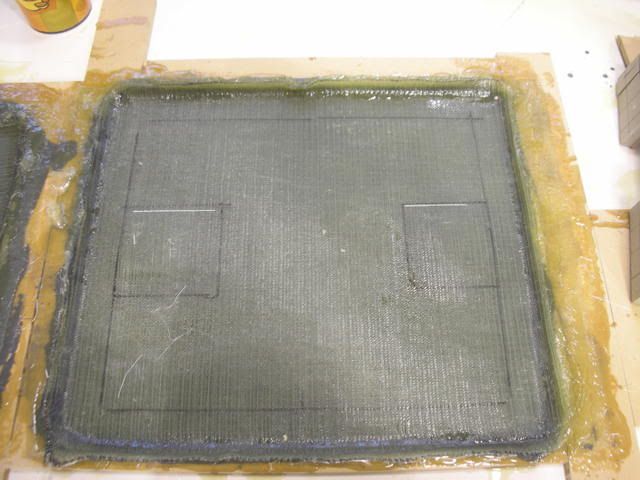

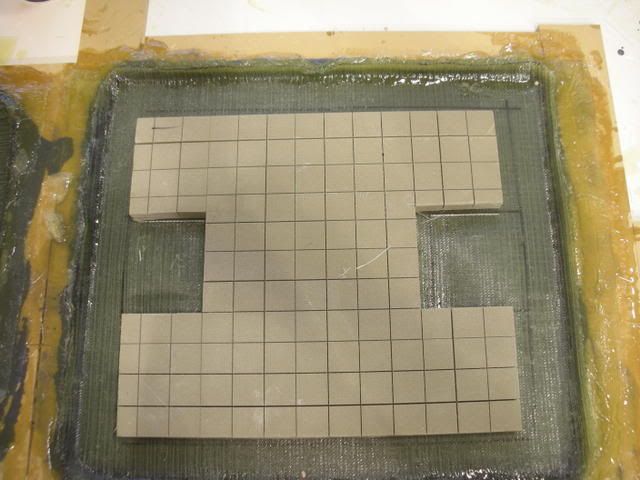

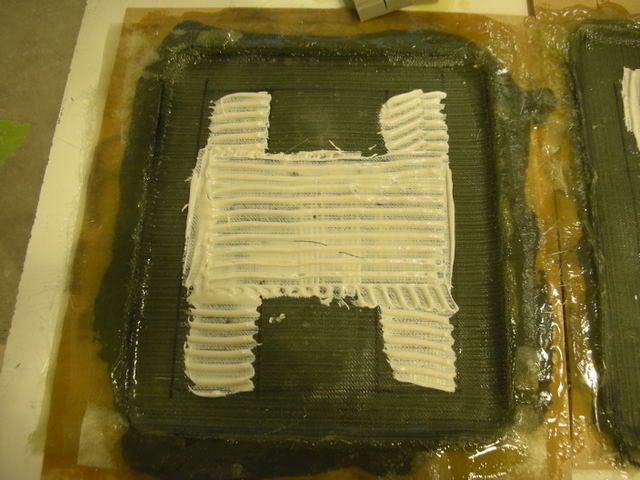

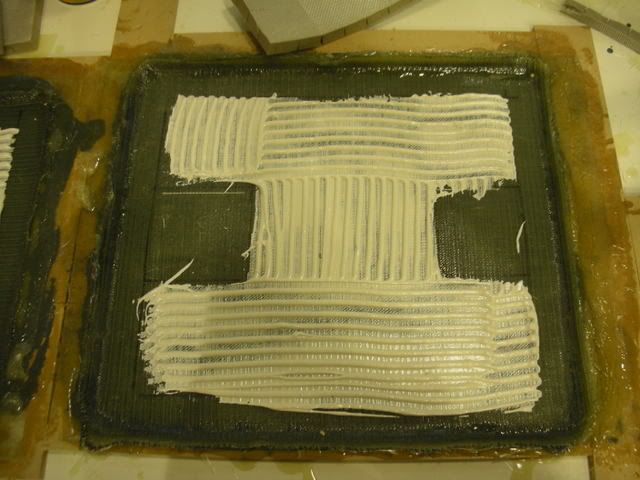

started building the hatches and the access plates for the fuel sending unit and the pick up tube   Duratec applied and first 2 skin coats of mat  here you can see where I put the wood circles in for the latches  after I applied another layer of mat, 3 layers of biaxial I layed out where the latches for the divynecel coring.  the divynacel dry fitted. I know I didnt take many pics when I was laying up the deck so I figured I would take a bunch of pics of how to layer the coring  here is the tile trowel again      They make a tool to bed the the coring but a Fein multimaster works fine to work the devilet putty up in the coring  after I layed a layer of mat and 2 more layers of biaxal cloth I popped them out of the mold and cut MOST of the flashing off with a table saw.  I did some research and bought a diamond tipped router wheel for my router from Bodi and went to work. This bit works perfect. You router around the top and it gives you a perfect flat surface on the bottom as it did.   here is the flashing getting cut off     I drilled the inner hole for the latches ans did a little dry fit. I used a peice of 1/4 inch poplar ply for the circles   I dry fitted the hatch to make sure it was going to fit! If I were to do it over I wouldnt have use the 1/2 wax radius putty I would have used the 1/4 to have a tigher fit. I can do it on the next boat!  In the dry fit I still have to take a little off the bottom still to make it flush with the deck.  I got my livewell from Tommy at Hammerhead boatworks, it is a really nice setup. Here are some pics  drains on both sides   He also put a 1 1/8 fitting in for me for more volume  that is it for now I am trying to have the boat ready for primer after the weekend. till next time

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

#77

|

|||

|

|||

|

great pictures. I am about to start my deck and transom replacments. Joe at Mertons is a great help and I am about to order my supplies from. I've known him for over 20 years.

Your pictures really help. I like the hatches but was wondering how you will keep water from going into bilge. |

|

#78

|

|||

|

|||

|

the 1/4 flange that is on the deck side of the opening is going to get sanded on both sides of the middle so the middle portion will be a high spot in the when the latches on bith sides are swung closed it will pull the hatch down. I also ordered high grade gasket material for the hatchs to form a tight seal around the hatch.

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

#79

|

|||

|

|||

|

Hey BTK . I need some gasket material and some dogs. What are you using? Nice work BTW.

Thx, GFS |

|

#80

|

|||

|

|||

|

Those latches are really nice. So the Multimaster was used to vibrate the bedding into the coring? Were is the bait tank going to be installed? great work on the hatches!

strick

__________________

"I always wanted to piss in the Rhine" (General George Patton upon entering Germany) |

|

|

|