|

|

#1

|

|||

|

|||

|

I am a new member that has been following repair/modification advice since I bought my 1976 23' SeaCraft a little more than a year ago. I am planning to post pictures with a short bio soon. I am in the middle of rebuilding due to an unfortunate chain of events and have run across something that I need some advice on. I dropped my boat off to a fiberglass shop here in the FL Panhandle to get the open transom glassed in and possibly a bait well in the transom above deck. After some core samples, I was informed that the wood in the transom was "wet but not rotten." I have had 3 mechanics working in and around the boat in the past 5 months and all of them commented on how solid the transom seemed. I am young (I just graduated college) and I am kinda feeling like I am being misled into buying a whole new transom because the guy doesn't want to piece work a transom together, which I can understand. I will be adding a flotation bracket when this ia all said and done. I guess what I'm asking is what are my options when the wood is "wet but not rotten." If there is any more info that would aid advice, please ask. Thanks.

|

|

#2

|

|||

|

|||

|

Welcome to CSC TwoWisemen,

If your transom is wet, the next thing to happen is rot. Two choices: Core drill and fill with epoxy, (like Gits Rot) or rebuild the whole transom, if you plan to keep the boat, you should spend the time and money to go through it. Just my 2 cents worth. Good Luck, See ya, Ken

__________________

See ya, Ken © |

|

#3

|

|||

|

|||

|

Humm, you'll probably find that most guys here have replaced their transoms. As rule of thumb a 30 year old transom is bad. Even boats that have sat in dry storage have had dry rotted transoms.

Though in a case like yours, having solid but wet core and putting a floatation bracket on, you have the option of using a bracket such as Hermco's which is designed for applications such as that, that stiffens up weak transoms. In my two cases I felt that wasn't an option even though I have a Hermo bracket. One was so rotted most of the wood actually fell out, in the other I had a massive blackant colony living in it. [img]/images/graemlins/frown.gif[/img] I'm sure Don will chime in here and give you the skinny. He's our resident expert.

__________________

http://lecharters.com '76 23 SC CC I/O '86 20 Aquasport 200 '98 15 Boaton Whaler Dauntless There's more but w/e |

|

#4

|

|||

|

|||

|

If the transom is still the original transom from 1976 the chances that your transom is still in good shape are very unlikely. If it was me I would replace it now. “when in doubt through it out” when it comes to boats and boat safety. That’s a 30 year piece of plywood with several holes that have been drilled in it and possibly have or have not been dealt with correctly. Plus you have the weight and torque of a 200 + hp motor sitting on the back for all those years. When I did my 1976 I had black mush in there.

Thanks to Jayson check out this www.classicseacraft.com/fellowship FellowShip _______________________________________________ My motto: Just for the Grins [img]/images/graemlins/grin.gif[/img] [img]/images/graemlins/grin.gif[/img] [img]/images/graemlins/grin.gif[/img] |

|

#5

|

|||

|

|||

|

First - Welcome - there is an incredible bunch of guys here, and a real wealth of knowledge -

I read your post, and have probably a half dozen questions- I get that you want to put a bracket on the back of your boat ? and what motor (s) are you hanging on the bracket - what I'm after there is the weight going on the bracket - so the wood was "wet- but not rotten" what kind of wet? any freshwater wetness Will lead to dry-rot - salt water wetness is kinder that way, but soggy plywood cores have all the strength of wet cardboard (I know from personal experience)- so how wet is wet - if you drill a small hole or two, down low in the transom, and water comes out, and continues to drain for awhile, you're soaked - How did the previous owner use / store the boat - on a trailer, under cover, in the water - how much did he trailer it, how much will you trailer it, over the road ? a bracket mount, especially with a heavy 4-stroke, or twins, will put much greater stress on the transom, than a single motor directly mounted on the transom - think lever - the longer the lever, the worse the stress - but at the same time, a large flotation style bracket, like the Seamark, spreads that load out over a wider area, than say an Armstrong style single motor bracket - spreading the load is a good thing. If multiple core holes confirm wet, but not rotten, then the transom could be dried with a pattern of holes, and some time, and then core soaked /filled with an extremely low viscosity epoxy - but if your going bracket, and thinking twins, or big heavy 4-stroke - I'd want a new transom, if it were me.... I know you said you just got out of college, and probably didn't want to hear this right now - it's beginning to sound expensive... but know that the seacraft 23 is one of the best riding hulls out there, so maybe you skip the transom close, dry and core soak the transom with epoxy, keep the motor on the transom, for now, and keep running it for a few more years, till you get a better feel for where you want to go with it ? just some questions and thoughts. good luck - and get some pix up for us !! Bill |

|

#6

|

|||

|

|||

|

The boat has been through alot, it was a charter boat out of Jax, a pleaseure boat on the Suwannee River(?!?), and then before I got it, sat in a barn for 3 yrs without touching the water. After I bought it, it spent 3 months with mechanics making sure everything was clean and lubricated. It had twin 150 Yamaha's and was very low in the back. Whoever had twin motors put on, had the transom raised 5" (I could tell when I removed them and started sanding off years worth of bottom paint). I could see where the old motor mount holes had been repaired by a resin coated dowel. To my knowledge, that is the proper way to repair those holes. I guess I'm reluctant because I've been had twice by different people since I've owned the boat and I can't afford to have work done that is not necessary, or to pay for work that doesn't get done. Thanks for the info, guys. I'll try to post some pictures this week.

|

|

#7

|

||||

|

||||

|

Welcome Wisemen to CSC

I have owned my 23' since 1985. I too thought my transom was solid as I keep things pretty well buttoned up. Boy was I mistaken!  Imagine if you left the 30 year old transom "as is" and mounted your bracket and engine and a year later because of the added stress you now need to replace it. You now have added extra expenses for de-rigging the motor and bracket [img]/images/graemlins/wink.gif[/img] IMO R E P L A C E the Transon now [img]/images/graemlins/wink.gif[/img]

__________________

1978 23' Superfish/Potter Bracket 250HP -------- as "Americans" you have the right to ...... "LIFE, LIBERTY and the PURSUIT of a Classic SeaCraft" -capt_chuck |

|

#8

|

|||

|

|||

|

OLDBLUESPLAYER-

Had twin 91 150 hp Yamaha's Going to single 99 250 Yamaha OX66 The boat has been on a trailer for the past 8 yrs (most of which was in a barn), before that, probably kept in the water (as it was a charter boat). I'm 30 miles from the farthest place I fish, usually 12 miles. I'm going to go pick up the boat from the fiberglass guy this week and then I can see for myself what he is talking about. I'm intrested in drying it if that is something I can do. I just got the ability to store it covered but it would still be open to humidity in the air. Is there a specific product I can read about to dry the transom? Then when I get the boat back, I can see exactly what I'm working with and see if it is a possibilty or if I just need to save for a few more months and get a whole new transom. I've started doing everything I can myself and so far I've been successful. As far as how it rides- you don't have to tell me. I've gone to some extent tring to keep and rebuild the boat since I've owned it. My best friend has a 25' Edgewater and my cousin only runs Contenders (25 & 31)...I still wouldn't give up the size and ride of my hull. Skipping the transom close is not an option for me... While rebuilding the trailer (everything but the frame), I kept the boat at my brother's boat slip on the coast. I would go check on it every 3 days or so and all was fine. After fishing ALL day on a Saturday, we were returing to fish again on Sunday to find it sunk in the slip. After getting all kinds of reasons from the insurance inspector (idoit). I finally figured out what happened. The self tensioning cables that were tied to the nose of the boat provided lift, the twin motor on the back of the boat, the location of the stock baitwell, and a poorly placed/sealed rigging tube allowed for water to come over the tramsom and into the hull. What was different that night from all the others is that the tensioning cables had more weight added because the boat was bumping against a piling in stronger winds, the bildge switch either was stuck or didn't function properly, and I wasn't holding my mouth just right. So as you can see, I'm not putting it back into the water until the transom is more than 3" above the waterline. Thanks again for your help and taking an intrest. I look forward to sharing stories... |

|

#9

|

|||

|

|||

|

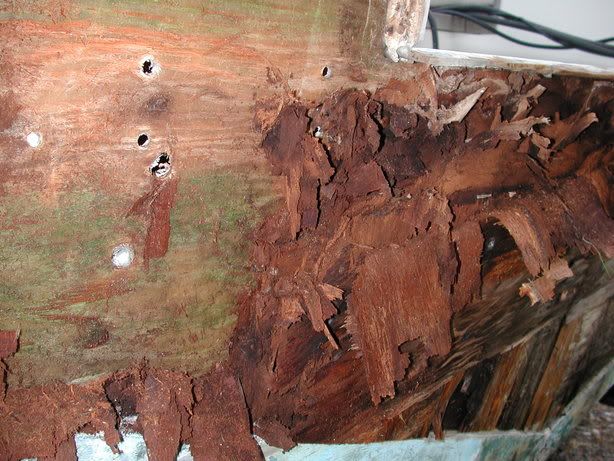

Hey Chuck, look at this one. Man I never thought for a minute it was good.

__________________

http://lecharters.com '76 23 SC CC I/O '86 20 Aquasport 200 '98 15 Boaton Whaler Dauntless There's more but w/e |

|

#10

|

|||

|

|||

|

The Rot Doctor

I worked on a 1958 Chris Craft lapstrake hull and used this stuff on the area around the rudder post and strut bolts and it worked great. I don't know about a wet transom ........... |

|

|

|