|

|

#51

|

|||

|

|||

|

Hope Carmen brings it to our Atlantic City get together this summer,,,

Hay Hay,,, Bruce,,,how bout having it in Ventnor LOL...I know someone with a house on the water there LOL... Joe R. 20ft Classic SeaCraft Susie II

__________________

Joe R |

|

#52

|

|||

|

|||

|

Thx man. I plan to have the deck in, in the next few days weather permitted. Ive been lurking around this site and classic mako for several years, just dont usually post......Lots of great info and craftsmanship on both sites.

|

|

#53

|

|||

|

|||

|

Quote:

We could do that, just gotta kick the renters out, lol. I'll be back from Jamaica by then.

__________________

Thank goodness that in the scheme of things you are broke, powerlesss and inconsequential, because with the shortsighted alternatives and idealogy you have you'd be much worse than those you complain about. |

|

#54

|

|||

|

|||

|

The back one is glassed down permanently. The next one will be down for good tomorrow. I was waiting on the gas lines which arrived at my door today. I love ebay. and UPS. then maybe the third this week end.

room for a couple 60 inch blue fins under the deck.   It sure seems like a big 20? I guess making a three piece boat is a big difference.Oh one or two more. I went a little anal on the helm pod.   No varnish either.

|

|

#55

|

|||

|

|||

|

You turn the grain nicely.

Cheers, Us |

|

#56

|

|||

|

|||

|

wow cant wait to see this finished. I really like the single level deck on the 20 I could definatly see the advantages

__________________

78' / 20SF / Merc XRi Black Max 150 |

|

#57

|

|||

|

|||

|

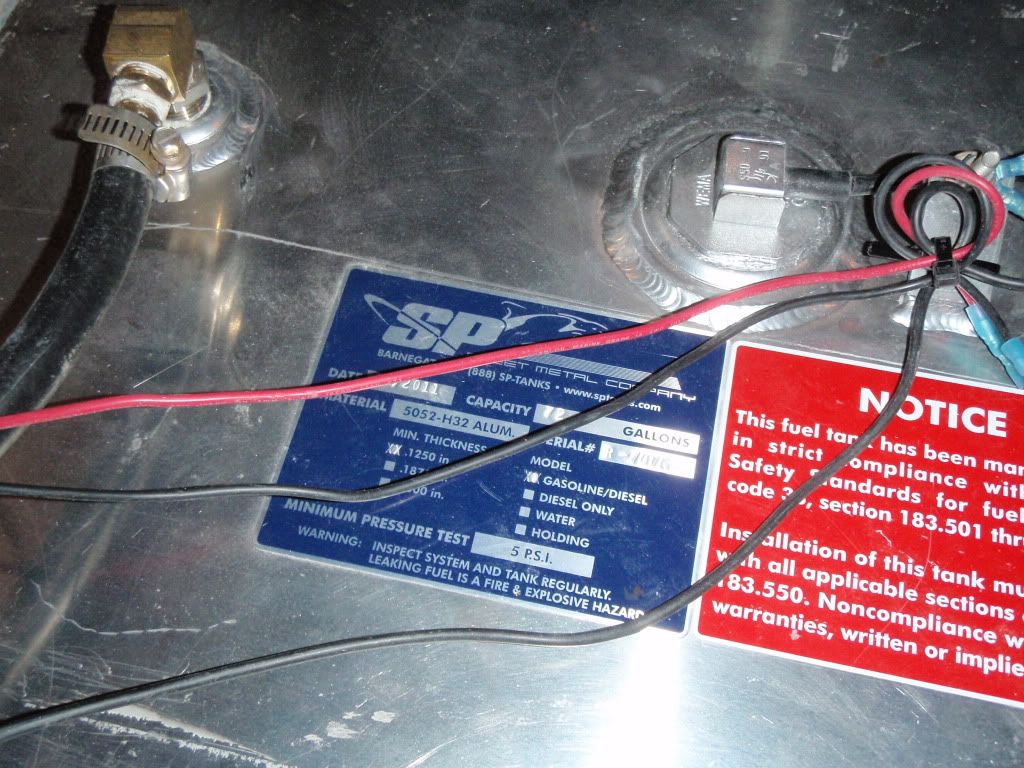

to be installed By S&P tanks. One of the bigger longer lasting companies still around. No foam around tank. It is bolted to the main stringers and sets on Neoprene pads installed under tank. If any water does get near tank it can drain away because of many openings or holes drilled in the fuel tank pad it sets on. Also all hoses have chafe protection . The grounds and fuel gauge wiring is done with shrink wrap connectors. I also tie off the wires with a loop and ties to Make sure No one can pull the crimped connectors a part.

I also glassed under the penske boards the old fashioned anti gravity way. On horses up side down.

|

|

#58

|

|||

|

|||

|

Lookin' real good Bly!!!

Nice to see a little Southern in a Northern boat..  Also, one suggestion. Double opposing stainless clamps on your vent and fuel lines. I learned the hard way!

__________________

See ya, Ken © |

|

#59

|

|||

|

|||

|

some years of boating and retiring as a pipe fitter working with hose clamps many times? If using a quality clamp I have never seen one fail. There have been many clamps I would not use tho. Then the other thing is on the fuel line pick up fitting? It was a actual Mueler fuel fitting I bought and not a plumbing fitting? So dont blame me. There is not room for two clamps unless I buy those thin clamps. A beefy clamp like I like will clamp mostly on bare hose and not the barbed fitting? I do not think that is good? Maybe since you proved My urban legend wrong I will atleast double the fill and vent hose. There is plenty of room on Those. I am not doubting you? I just thought if I have not ever seen one fail it must be one of those urban legends? Like not putting a battery on a cold concrete floor? That was when batteries were made with glass?

|

|

#60

|

|||

|

|||

|

Well I hear ya' bly....

I have always used nothing but the best around in hardware and materials, when doing a boat.. (not just SeaCrafts) I had a 308 stainless clamp that the worm screw just fell out!  It had not been over tightened if that is what you are guessing.. Luckily it was on an exposed fuel line on a 15 Whaler I had previously owned! A friend in the marine business recommended double clamps, keep in mind this was over 30 years ago with that tip. I have adhered to that standard ever since.. Everyone has their way, this is just mine!

__________________

See ya, Ken © |

|

|

|