|

|

|

|

#1

|

|||

|

|||

|

alright I decided to re use the large front hatch and the bow hatch as my bilge hatch. They were close to size I wanted and they are already built. I know I will have to recore them but the hard work is done. So for my mold table I got some 3/4" MDF for the plugs. I added a 1/8" al the way around with a piece of luan. I then gave the radius of the corners with a steady hand and a pencil....

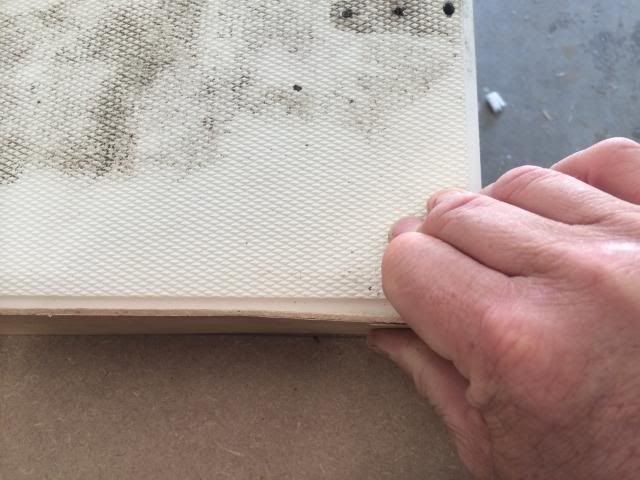

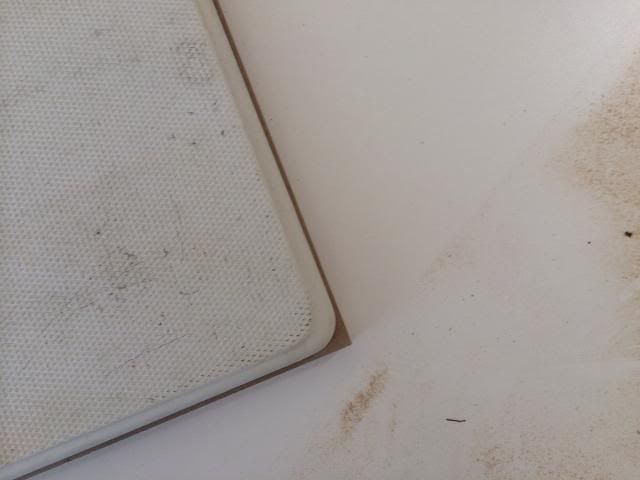

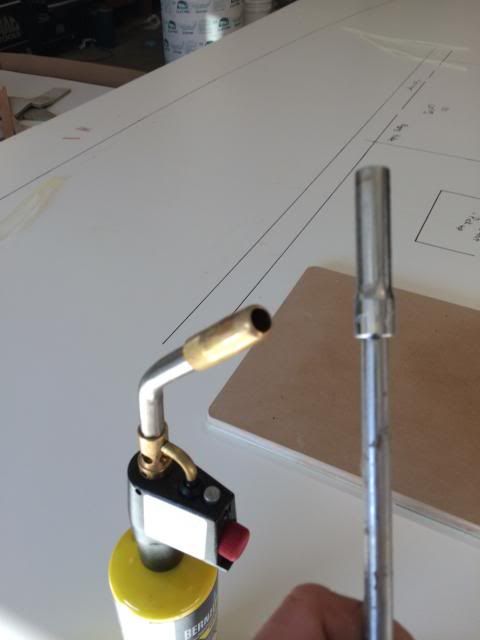

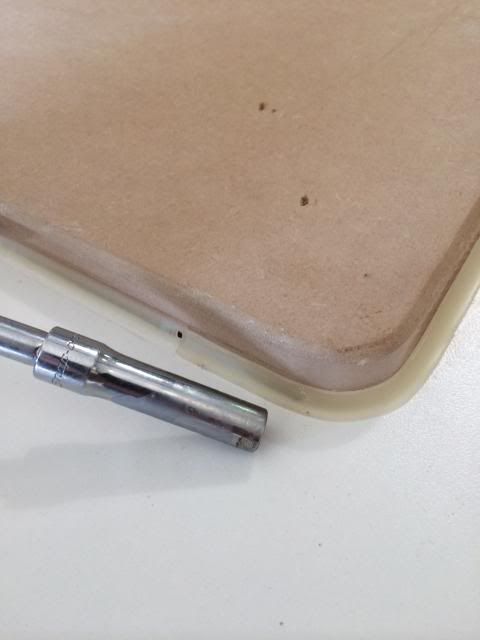

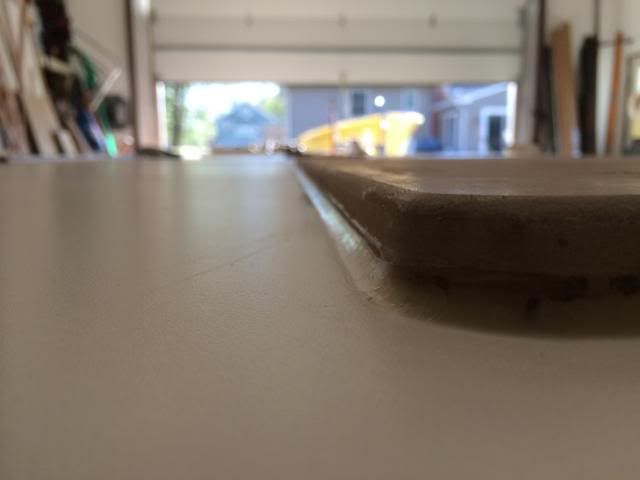

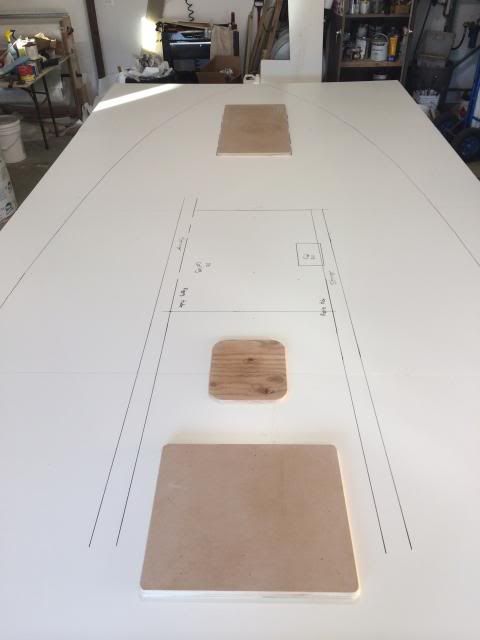

here I have the luan pushed up against the hatch to give myself 1/8"      After I cut everything to the size I needed I put a small radius around the top of it and fit them into place. Next came the radius wax that I got from Joe Merton (merton fiberglass). Basically I put it down in place and use a socket on an extenstion to radius around the plugs. I use a little heat to melt it into place.    I have the three plugs in place and waxed up. I have the layout of the stringers and the fuel fill also the rigging tubes. I am not gonna core a certain area under the console so I can make some cuts later and don't have to be so exact. the plugs you see are the bilge hatch, fuel sending unit/pick up and the front hatch

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

#2

|

|||

|

|||

|

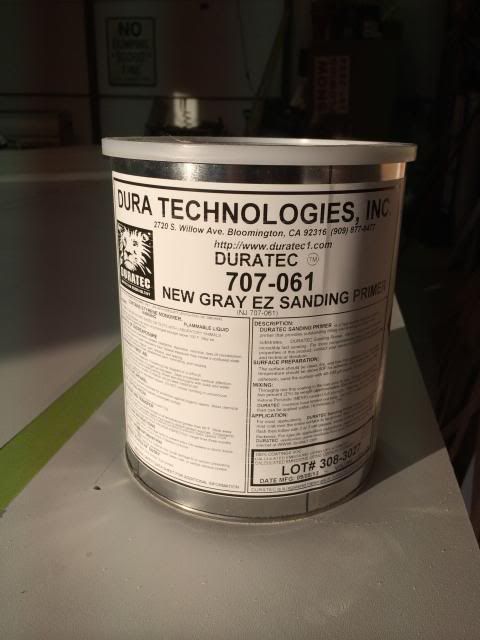

well I got a good start on the deck this weekend I got the duratec sprayed, 2 layers of mat down, and then the 3rd layer of mat and 1708 down. I needed help for the durtec and skin coat. So my my friend Mark came by and we kicked its ass. We sprayed the duratec and put the skin coat down in 2 hours. With 40 minutes of primer kicking off.

I cut all the glass the day before and had it rolled up and marked for laminating    Mark is the man with the cup gun. He has been doing this a long time, there was no sense in me getting in his way. I mixed and kept the cup gun fed. We used 1.5 gallons of duratec for the deck build      here is how we set the mat to laminate, when the flop over they are over lapping by about an 1"

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

#3

|

|||

|

|||

|

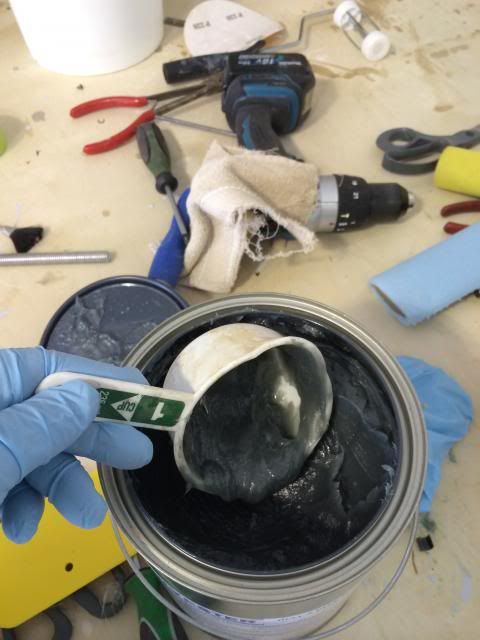

Mark had to go after the first coat was down so I figured I could get the second coat down myself. I got it done but don't think I would attempt it again. It was too much rolling, mixing and laminating for one person.... I used deck putty from Joe mertons to fill the radius of the hatches to give the 1708 an easier flow over them.

With the second coat applied and some time to kill I decided to blend the old engine box and console together. I first cut 3" off the console with the air trimmer, Which I still think is one of the best ways to cut fiberglass anyway. That newer console I cut had to be one of the thickest consoles ever made. It was 1/2" thick in the corners. It took about 3 hours and a lot of head scratching along with cutting/ fitting, cutting/fitting and it finally came together. I am gonna build a livewell into it and glass it into one.

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

#4

|

|||

|

|||

|

I like the idea with the console and using the engine hatch!

__________________

Current SeaCraft projects: 68 27' SeaCraft Race boat 71 20' SeaCraft CC sf 73 23' SeaCraft CC sf 74 20' SeaCraft Sceptre 74 20' SeaCraft CC sf |

|

#5

|

|||

|

|||

|

got the coring all dry fitted , it took 7 4'x4' sheets to cut and fit everything with enough left over to do the hatches. I put corelite down where the console and leaning post will be mounted.

after everything is dry fitted, I mark everything to make it easy to reinstall after the I apply the divelette putty.   I ran out of putty and have to get more tomorrow. I got the back half of the boat all puttied into place.

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

#6

|

|||

|

|||

|

I am REALLY glad you decided to finish this and not sell it. Seeing the craftsmanship of your work is awesome - please keep up the documentation - I have a lot to learn.

|

|

#7

|

|||

|

|||

|

guys thank you for the motivation.

lord that console is bad ass, I hope mine can look that good when its finished. does the livewell pressurized? got all the coring done and back filled around the hatches with deck putty and layed th final layer of mat,roving here you can see the trawl lines for the devilette putty this is how to bed the coring.  my multimaster has seen been days   still maintaining the 1/4" crown  I alright I saw my masons using these to fill the cracks between the bricks and I thought I would try them, got them from home depot for a couple bucks apiece. they really worked well for controlled putty, filleting  this is the easiest way I found to fill them    nice and smooth with no goobers or spillage

__________________

36' Yellowfin 1972 20' seacraft 140 suzuki http://www.classicseacraft.com/commu...ad.php?t=18607 |

|

|

|