|

|

|||||||

|

|

|

Thread Tools | Search this Thread | Display Modes |

|

|

|

#1

|

|||

|

|||

|

Posted this project on tht and haven't gotten much help, so I thought I'd ask over here too

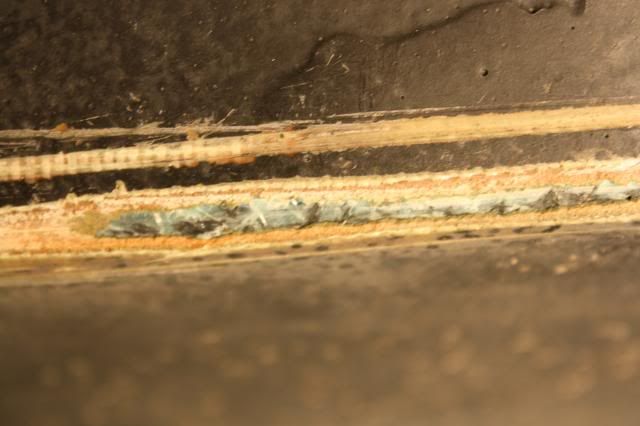

Last year I noticed that there were strips of biaxial tape on the sponsons of our '87 Boston Whaler 13' that were beginning to delaminate. The plan was to pull the tape and see what it was hiding, but this year when we pulled the boat home I noticed salt deposits on cracks in the tape, signifying possible water intrusion, which really got me concerned. The plan is to sand off the tape with an orbital sander to better asses the situation, and then repair. I'm not totally sure how to go about the repair, but I do know epoxy, fiberglass matt, and a fairing compound will be involved. The damage is in a high abrasion area on the hull so my thoughts are to grind out the damaged area, build back up with chopped glass and epoxy mash, grind to shape, fair, lay a layer of 2 of matt down, sand the matt and finish off with a thin layer of fairing compound followed by bottom paint. This is my first fiberglass project and would like to finish with a quality product. Here are some pictures of the damage (Ive began to pull back some of the tape, and it appears that there are 2 layers of tape (1708?) covering up some pretty minor damage, but ive only uncovered a small part of it. My hope is that the salt deposits were formed from water that was trapped between the hull and the tape, and not water that had found its way into the foam core): Starboard Sponson:    Keel needs some help too:   Port Sponson:   What looks to be impact damage on the underside of the bow, I will look into that as well because there was a similar salt deposit formed on those cracks too:  I would like to have the boat at least watertight for Memorial Day weekend, because we have a trip down to Mustic Seaport. It will just be slow no wake running in the river, no hard running. Ill finish the repair correctly when we get back. My main question is what weight mat should I be using? Thanks! |

|

#2

|

|||

|

|||

|

Epoxy resin will give you higher bond strength than poly, so I agree with your choice. Chopped strand mat, however, is held together with a binder that dissolves in poly resin, but not in epoxy. I think I read somewhere that they're now making a CSM that works with epoxy, but I've never seen it. Here's a good article on the subject:

http://www.westsystem.com/ss/chopped-strand-mat-epoxy/ With epoxy resin, I would use a light weight cloth, say 10 oz. to go over superficial damage. If the damage goes all the way through the laminate, you should grind it out and go back with a full thickness repair that tapers out on both sides so it's about 12 times as wide as the laminate is thick. Dave

__________________

Blue Heron Boat Works Reinventing the wheel, one spoke at a time. |

|

#3

|

|||

|

|||

|

Thanks for the advise on the CSM, I had no clue! Whaler rec I ends it for repairs. My plan was to make sort of a mash with the mat to shove into the hole in the hull to try to get it to bite to the back side of the hull lay up. Then I will finish off the repair with cloth. I guess the weight if the CSM doesn't really matter if I'm cutting it up, but what type of cloth should I use? Also what fairing compound do you guys reccomend? Thanks for the help, I'm a total fiberglass noob and just want to make as good of a repair as I possibly can.

|

|

|

|